TOWER RENOVATION PROJECT

About the Tower

The 165-foot freestanding tower has been a fixture of the Columbus skyline and beacon for the congration and the community since it was constructed in 1942. Architect Eliel Saarinen's design for First Christian Church put both the congregation and the community on the national design stage as one of the first Modernist religious designs in the United States. The tower recently received some much needed repairs.

December 18-29

A & B -The tower construction has gone well. As we reached having the project end in sight, Wilhelm ran into their first real hiccup. The plaza area did not have enough of an accelerant admixture in the concrete as it was poured for it to adequately set up for finishing in the cooler weather. Consequently when the concrete was power washed the next day, too much of the surface was removed exposing more aggregate than desired and damaging the edges of the saw-cut control joints. Because they were not satisfied with the quality of their work, Wilhelm immediately made arrangements to remove and replace the entire concrete plaza area. These photos are of the "new" plaza with the unacceptable concrete finish, being removed.

C -The photo below is of the work being done re-pouring and finishing the plaza the second time. A different crew was brought in to complete this work.

D - The reworked plaza is being power washed and Wilhelm will do a final site cleanup and the project will be complete. Landscaping of the lawn adjacent to the tower, damaged during construction will be redone in the spring.

A

B

C

D

December 12-17

A -Work this week continued on the plaza in front of the church. The sidewalk pours were two, two-day processes. On the first day, the concrete was delivered and placed within the forms, rough leveled with a screed, then trowled and bull floated to "smooth" it out, and edged. On the second day after the concrete has set, it is cut with a diamond bladed saw into large sections which are relatively square. By doing this the concrete will crack in the sawcut joint, known as a control joint, and not through the finished slab. The slab will continue to cure or "harden" for about 4 weeks at which time it will be near its maximum strength. The final step, on the second day of the pour process, is to power wash the finished surface to expose the sand and stone in the concrete which was chosen to closely match concrete surfaces nearby in texture and color. The new concrete is mixed with special agents and covered with large insulated blankets to prevent it from freezing as the initial curing takes place.

B -Overall, with the new curb and plaza area, approximately 105 cubic yards or 12 truck loads of concrete were poured and finished over the 4 day period. Below, the slab poured on the first day has cured overnight and has been sawcut and it is being power washed to expose the specified color and texture.

A

B

December 4-8

A & B -Except for cleanup, the work on the tower is done. The focus now is replacing the plaza area and curb in front of the church. Wilhelm has completed the demolition of the concrete and it was hauled away for disposal. New concrete will be installed, in 6" depth directly in front of the tower and stairway to the courtyard. The plaza area in front of the steps to the church entrance out to the street will be 4" thick.

C -Earlier in the project Wilhelm and Louis Joyner worked together to develop a recipe for a concrete mix that would replicate the existing plaza in both color and texture. Three samples were poured and the one in the upper right of the photo below was selected.

D -Fifth Street was reduced to one lane to allow the concrete trucks room to dispense the material and the finishers to work safely while forming and pouring the new curb.

A

B

C

November 27- December 1

A -Work this week continues to focus on the clean-up and putting things back together. Some of the limestone step treads into the courtyard were removed to accommodate the base of one of the work platforms. Wilhelm employees are seen replacing those stair pieces below. In addition, in the same photo, four darker gray limestone panels, on the vertical wall just above the kneeling worker, have been replaced because of their poor condition. They will be treated to better color match the existing panels.

B & C -Below (B) is a photo of the new clock drive unit. It is entirely enclosed in the white cylinder, which is about the size of a gallon paint can. The mechanism is controlled from a cell phone app and will automatically change time between DST and standard time. The new clock was started on 11/28/2023 at 10 AM. The photo (C) is the original Seth Thomas clock movement installed in 1942.

D & E -In the lowest level of the tower, a fan has been installed to pull air into the tower and push it up through the interior to be exhausted. The space within the tower will be monitored for temperature and humidity and warmed in fall and spring when temperatures vary widely. This will prevent moisture from condensing on the interior walls and causing failure to the bricks on the inside of the tower. The D photo is the brickwork covering the damper on the south side of the tower's base. The E photo is the intake fan that will push the warmed air up through the tower.

F - The tower door has been reinstalled after being rebuilt to its original design after removing an exhaust fan that had been attached to help remove moisture from the tower interior. This photo also shows the new brickwork just above the door where a rusted lintel has been replaced.

A

B

C

D

E

F

November 20-22

A & B -Updates to this point have focused on work that has taken place on the exterior of the tower. However, much has been done on the interior also. A significant structure of square tubing has been added to the 5th floor and bell chamber above it, to strengthen the uppermost portion of the tower to prevent it from twisting and cracking again. Earlier photos showed this ironwork from the exterior but those below show it from the 5th floor (A) and bell chamber floors (B) looking up.

C -The tower door has been returned from the company that refurbished it. They rebuilt the section that had been modified years ago to accomodate a fan installed to aid in the tower's ventilation. Since the tower is now temperature controlled during the spring and fall months to prevent moisture buildup on the interior walls, all openings in the tower structure are now controlled by intake dampers and exhaust vents. The door is shown below in preparation for re-installation.

D -Wilhelm employees are in the process of removing equipment and materials from the tower work areas. The photos below are of that work going on.

A

B

C

D

October 23 - November 3

A & B -The clock face has returned from St. Louis where it has been cleaned and refinished and was bolted to the tower face. New hands and a drive unit for the clock were also installed and it will be able to be contorlled and adjusted from the ground level using a cellular phone.

C & D -The completion of the masonry on the parapet walls and the corners of the outer clock chamber were the focus of the past two work weeks. The tower walls will be cleaned in preparation for the final staining and colore matching. Wilhelm bricklayers are seen finishing their work around the parapet (C). Photo D is looking straight down on the tower from above, with the new rubber membrane roof in the center and work platforms on the east and west faces. Both of these photos were taken from a drone.

E -One the work on the tower is done, and the equipment and materials are removed, the entire plaza in front of the church will be torn up and replaced. Here are 3 samples of concrete poured to review the texture and colore in an effort to match that of the existing concrete area.

F & G - The sheen on the tower in photo F is the result of water from power washing to remove all of the dust and dried on saw cut dust from the various repairs completed on the brickwork. In phot G is a closer view of the washing process. This is being done to remove all of the debris from the construction and to allow the contractor, that is going to stain the new bricks to match the original, the best perspective of what they are working with.

A

B

C

D

E

F

G

October 9 - 20

A -The upper clock chamber limestone and brickwork on the west face (below) was completed on October 7. The brick on the upper parapet wall above the limestone still needs to be finished. The white strip above the upper row of panels is an aluminum flashing that will be covered with brick when the parapet is complete. It is in place to prevent damage from rain water getting behind the limestone.

B & C - Limestone and brickwork on the south wall is also complete. The first row of limestone panels (B) on the east side of the tower were set on 10/10 and the last row (C) was completed on 10/20.

D & E -New galvanized ladders, floor grating and frames have arrived and are ready for installation. These will replace the existing 81 year old items in the tower interior and were considered to be a safety hazard because of their corroded state.

A

B

C

D

E

September 25 - October 6

A & B - The zipper is (A) complete and Wilhelm is now focusing on the clock chamber grid. Work is happening on all four sides of the tower. In addition, on the inside (B), new sump pumps and piping have been installed, along with controls and lighting in the pump room. Water from the courtyard and tower roof collects in a sump below the floor and then is pumped to the city for disposal.

C & D - The limestone panel patterns are different between the zipper (C) and upper grid (D) as can be seen in the photos below.

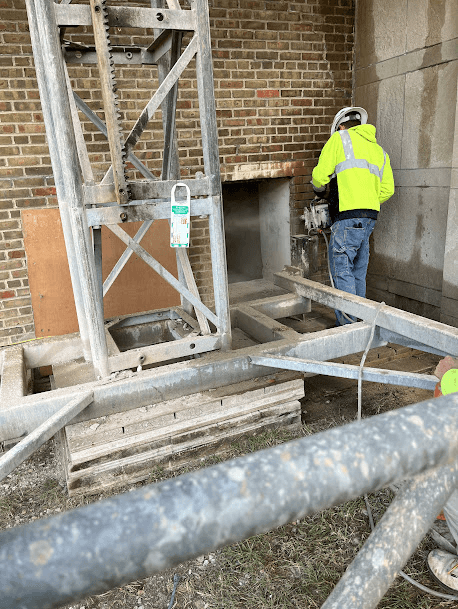

E - To prevent moisture from accumulating on the inner brick walls of the tower during the spring and fall seasons, tempered air will be moved through the inside of the tower to keep the walls dry and prevent the interior brick from spalling. A new exhaust fan will be installed on the roof and a dampered opening will be added at the base to allow air to enter and exit in a controlled manner. The fan, damper and a small electric heater will control the inside air to prevent moisture buildup and brick damage. Workers in the photo below are saw-cutting the opening in the base for the damper and Wilhelm will build a brick grating over it.

F & G - The bricks in the hopper (F) have been cleaned, reclaimed and ready to be hoisted to the work platforms for reuse and the bricks in the background are new and will be mixed with the old and stained to match. The photo labeld G shows the crane lifting the hopper of bricks to the platform.

A

B

C

D

E

F

G

September 11-22

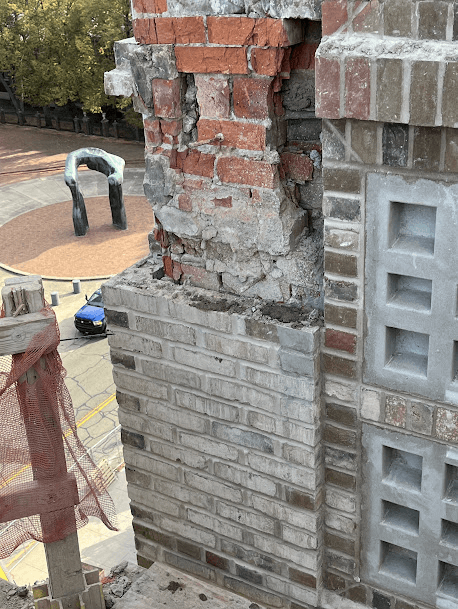

A & B - Work is continuing to rebuild the zipper (A) and the adjacent brick along the NW corner of the tower. A close-up photo (B) depicts the damage that was the result of the original open grid construction of the zipper. Freezing and thawing of water that entered through openings in the structure accumulated there, causing this condition. In later years the area behind the open zipper was sealed off and backed up with reinforced concrete to strengthen and seal that portion of the tower but the damage had already been done.

C & D - Workers (C) are on site staining the new bricks that will be mixed with the original bricks and added to those that were salvaged and cleaned for reuse. Bricks with the diagonal cuts, (D) are being stained in preparation for use in the corners of each limestone panel in the zipper and upper clock chamber. Once in place on the tower walls, final staining will continue on brickes in areas where necessary.

E & F - The tower is being power washed (E) to remove all of the dust and debris that has accumulated during initial stages of construction. This is being done to ensure that smaller cracks (F) are visible so repairs can be made. The cracked bricks have been saw-cut ("black lines" on the bricks) for removal. Additional cleaning will be done prior to the final staining process.

G - This is a close-up of a limestone zipper panel and its brick trim (rowlock course) being placed to appear as four separate panels when completed. Only one panel, which weighs about 1000 lbs, can be set every day to allow the concrete mortar between the bricks to set and strengthen. The concrete block wall, that can be seen, is new and is attached to the concrete patch that was added behind the zipper in the early years of the tower when water and ice damage (mentioned above) was observed.

A

B

C

D

E

D

G

August 28 - September 8

A - As indicated earlier, the NE corner of the tower (zipper area) has received special attention because of the damage that has occurred from excessive brick movement. The zipper interior has been rebuilt with concrete blocks that have been filled solid with concrete and rebar and then tied horizontally into the existing brick. Reconstructing the corner exterior brickwork has started as seen in the photo on the left. New limestone panels and perimeter brick trim around the panels, also as seen below in the right photo, to replicate the original zipper and match the upper east and west walls in the bell chamber, is now underway. The reconstruction of the zipper exterior can only be done one limestone panel every day because the mortar between each panel needs to set before a new panel can be added above.

B - Each limestone zipper grid panel weighs approximately 1,000 lbs. When trimmed with brick, the panels will appear as 4 separate limestone inserts in the brick zipper and upper clock chamber walls.

A

B

August 14 - 25

A & B - Wilhelm continues to remove and replace brick on the faces of the tower. In photo B one can see the new brick surrounded by a lighter colored mortar. These bricks and mortar will be cleaned and stained to match the tower's existing brick pattern.

C & D - The tower's NW corner adjacent to the "zipper" openings has deteriorated much more than the other three corners. Engineers have summarized this was due to the impact that the original zipper openings had on the overall tower structure. In the early years of its existence significant cracking was observed in this area. The remedy, installed in the mid 70's, was to pour in-place a concrete backup (patch) to the NW corner on the inside of the tower. The thinking was that this addition would stop or at least slow down the damage from the structure's movement in this area. Because of the relative excessive displacement and the damage it caused, this corner is having to undergo more repairs than the other three. The impact of the movement to the zipper frames, corner brick and the masonry on the north face can be seen in the photos below. Also one can observe one side of the reinforcing concrete patch placed on the inside of the tower zipper.

E & F - The original zipper repair plan was to replace the horizontal steel lintels with new and then add the brick frame for the limestone panels to the lintels. But, after seeing the damage underneath the face brick in and around the zipper, the engineers developed a new fix. The lintels are being removed entirely and will not be replaced. A new continuous concrete block wall is being installed up the NW corner openings. New brick and limestone panels will then be added and attached to the block to replicate the original appearance. In the photo below the new concrete block wall is being constructed in the zipper and which will then be refaced with limestone and brick to replicate the original design.

A

B

C

D

E

F

July 31 - August 11

A - Recent work has focused on tying the original brick north and south faces of the clock chamber to the new concrete block walls facing east and west. This can be seen by the horizontal lines on each corner of the tower's clock chamber block walls. These lines are actually stainless steel cables that are epoxied into holes drilled into the brick and then turned 90 degrees and epoxied into cut grooves in the new block walls.

B - Work has begun on the interior. The existing corroded steel grates have been removed and the openings in each floor are being cleaned and refurbished. New galvanized steel frames and grating will be installed along with lighting and roof and floor drainage piping. The photo below is taken from the first floor looking up through the openings in each floor to the roof.

C & D - New bricks are arriving and being stained. These pieces will be used to repair the frames around the "zipper" window frames and rebuild the clock chamber exterior grid around new limestone panels. Others will supplement original brick and will fill in where damaged bricks are cut out and removed in the tower walls. Some bricks will be stained prior to installation and then possibly restained or "touched up" in place after installation.

A

B

C

D

July 17 - 28

A - Concrete block walls on the east and west faces are now complete along with the parapet walls on all 4 sides. Structurally this is a major milestone. The walls and inner support steel that have been added in the clock chamber and level immediately below, will greatly improve the tower's stability. In the photo below, you can see where "new" bricks are being added to the areas where damaged bricks have been removed. These bricks and the area around them will be cleaned and stained if necessary to match and blend in with the original brick.

B - The parapet wall completed at the top of the tower.

C - A closeup of exposed brick at the top of the tower typical of the conditions found on the north and south faces. The bricks that are "sticking out" are those in a header position and will remain unless they are damaged beyond reuse. The outer course of horizontal or stretcher bricks have been removed. Mortar between the header bricks is in the process of being removed. When courses of new stretcher brick are added back then all of the joints will be cleaned, filled with new mortar, struck, cleaned again and stained to match the old brick if necessary. Also you can see pins that have been added over the years to help hold the brick together where significant cracking was observed to help hold the tower face together until permanent repairs, that we are undertaking now, are complete.

A

B

C

July 3 - 14

Wilhelm continues the tower reconstruction, with both the east and west upper inner concrete masonry unit (CMU) walls or more commonly known as concrete block walls now complete. These new walls, in the upper chamber, are significantly more complex than what is seen from the outside. Before the new wall is started, holes for 3/4" stainless steel 4' long all-thread bars are drilled starting at the bottom and then horizontally every 10' into the existing north and south tower walls. The all-thread rods are then epoxied 12" into the existing brick. The 36" remaining portion of the bar extends horizontally and is then tied together horizontally across the block courses by adding 3/4" rebar to the epoxied bars on the opposite face connecting the two walls. Holes for vertical rebar are drilled into the existing horizontal brick wall at the base every 8" and this rebar is epoxied into place. Concrete block is then laid horizontally across the face in 8" courses. All of the block center cavities are then filled with concrete and sections of 3/4" rebar are inserted into the wet concrete. After curing, what results is a solid CMU wall reinforced vertically and horizontally and tied into the existing north and south brick walls. After curing, the block walls will be faced with a limestone and brick emulating the original grid openings. This design and build will result in a significantly stronger and more stable tower.

West clock chamber inner wall complete.

This shows the inside of the tower with new steel bracing permanently attached to the wall. This is on level E, which is just below the clock chamber. This steel along with the new steel structure in the clock chamber will help to further strengthen the whole tower.

June 30

New eastern concrete block inner wall.

Western wall underway.

Water and its freezing and thawing over the tower's 80+ year life, has caused a significant amount of damage high on the tower's NW corner. The weakened brick will be removed and the architect, engineer and contractors have devised a fix using stainless steel cable, rebar and epoxy mortar to stabilize the existing wall, rebuild the damaged sections and eventually tie it all together forming new stable wall sections.

Deteriorated brick on NW Corner

SS Cable, rebar and epoxy mortar

Water and its freezing and thawing ovWilhelm has been able to salvage more than 80% of the existing exterior face brick to be reused. This will reduce the quantity of new bricks that will be necessary to be used and manually stained to match the existing brick colors and pattern. Below is a mockup built of new bricks placed adjacent to the tower. Three companies were invited to create these mockups to demonstrate their ability to match the brickwork in the original tower. All of the tower brick from repairs completed in earlier years that do not match will be stained to fit the overall brick pattern.er the tower's 80+ year life, has caused a significant amount of damage high on the tower's NW corner. The weakened brick will be removed and the architect, engineer and contractors have devised a fix using stainless steel cable, rebar and epoxy mortar to stabilize the existing wall, rebuild the damaged sections and eventually tie it all together forming new stable wall sections.

New brick and mortar mockup adjacent to the original tower wall.

Week of June 27

Tower reconstruction is progressing well. The interior block wall on the eastern side of the upper third is complete and tied into the original north and south walls. Wilhelm is completing the parapet wall (perimeter wall above the roof) on the east side.

Work has begun removing the brick around the window openings on the west side. Similar to the east side a new concrete block wall will be constructed to stiffen and strengthn that portion of the tower. Loose and damaged bricks are also being removed from the tower face on all sides. Some of these bricks will be cleaned if they are structurally sound and so far about 80 % of the exterior brick can be reused which is better than anticipated.

Week of June 9

Work has begun installing the interior concrete block wall on the east side of the upper third of the tower (area immediately below the platform) in the area where the "windows" were. This wall and its companion block wall on the west side will further strengthen the upper third of the tower when completed. These walls will be faced with a brick grid and limestone panels replicating the previous window layout.

A third sample (farthest right) of brick and mortar has been built for comparison to the existing combination on the exterior of the 81 year old tower.

Just below the platform in the above photo, bricks and mortar have been removed (dark spots) because they were damaged beyond repair. New bricks will be mortared in place.

Large batch mortar mixers have been moved in by F. A. Wilhelm, the contractor, to allow for blending cement, sand, and water creating the necessary mortar in both strength and color for brick replacement and tuck pointing.

A truckload of premixed cement and aggregate to result in the required mortar color has been received and is being unloaded.

Week of May 26

The brick window framework from the east side of the tower around the "window" openings has been completely removed exposing the newly added structural steel which will remain. From this same photo, workers are removing the clock face which will be cleaned, refinished and added back with a new clock mechanism. Demolition has also started on the west face. A temporary roof drain line is in place on the exterior of the clock face (not visible in this photo) for rainwater to escape without interfering with day to day operations.

In an earlier update brick reclamation was mentioned. In the photo below one can see the recovered brick wrapped in shrink wrap. The limestone coping stacked adjacent to the construction building will also be cleaned and returned to the top of the tower parapet wall. The brick in the foreground will have the old mortar chipped off, cleaned and stacked for reuse. The reusable bricks are all from the exterior of the tower which the contractor will reinstall to help color match the old and new sections of the repairs.

The clock face has been removed to be cleaned and painted. New hands have been ordered and will be installed on a modern motor and drive unit that will keep accurate time and spring forward and fall back with ease.

Week of May 15

The pedestrian walkway to the courtyard from Fifth St. has been improved and better covered to protect those who need to enter the courtyard area.

The cleaning and salvaing of the face brick being removed from the tower exterior is going well. Approximately 70% of this brick is able to be cleaned and temporarily stored for reuse. This will result in the process of color matching the "new" brick with the original being a little less difficult.

Minor changes to the limestone panels (photo in update above) have been approved so the supplier can proceed with cutting the new panels to replace the fiberglass coverings over the existing openings.

Progress on the tower removing sections of the wall on the east face above and around the openings has progressed this week. One can see the newly added gray steel structure which will support the remaining brick structure while the removed areas are reworked. This framework will remain in place once the tower is complete which will "stiffen" the upper third of the tower.

Week of May 2 & May 8

Much work is being done in the clock section adding structural steel that will support the north and south tower walls while the existing grills on the east and west side walls are removed and rebuilt.

Two potential exterior brick suppliers have constructed brick and mortar samples for review. One will be selected by the Architect. This brick, along with salvageable existing brick, will be used to reconstruct the tower grid and patch other areas on the tower exterior walls. Mortar samples for color matching of the existing mortar have been prepared and are being reviewed by LJA.

A sample of the limestone block that will be used in the vertical "zipper" on the west wall and in the upper grid has been received for review. Minor revisions will be made before the final blocks are cut for use.

The fourth and last work platform to allow exterior brick replacement and repair is being installed. Deconstruction of the parapet wall around the roof has begun. This wall and the roof will be removed to allow for the beginning of the teardown of the brick gridwork around the upper openings.

Structural work inside the top third of the tower is complete and the roof has been removed. The exterior brick rework on the north wall (clock face wall) has begun. Bricks that are salvageable are being carefully handled, cleaned and saved and will be reused. The horizontal rows of brick that can be seen in this photo on the clock face wall, where the brick is being reworked, are bricks placed in a "header" position every 7th row. This pattern is common throughout the church. The 6 rows of brick in between the header rows are laid in the "stretcher" position. The header rows tie the brick face back into the tower structure.

The 4th work platform has been completed allowing work now to proceed on all 4 sides of the tower. The platforms can be tied together to all move up and down the tower together or individually if necessary. In each platform section is a smaller portion that can be moved up and down independently from the main platform. This allows the removed bricks to be lowered to the ground in a safe manner. Salvageable brick can then be sorted and cleaned for reuse back on the tower.

The clock hands have been removed and will be replaced. A new modern clock motor and gear mechanism has been selected and will allow for the clock to be adjusted between daylight savings and standard time from an iPhone.